Beworth Tour in Golden autumn

Update:2017-12-08 11:12:49

Beworth invited clients to visit plant from 25 Nov. 2017, in duration of 21 days, 1,000 clients stayed in Beworth to enjoy Golden autumn time.

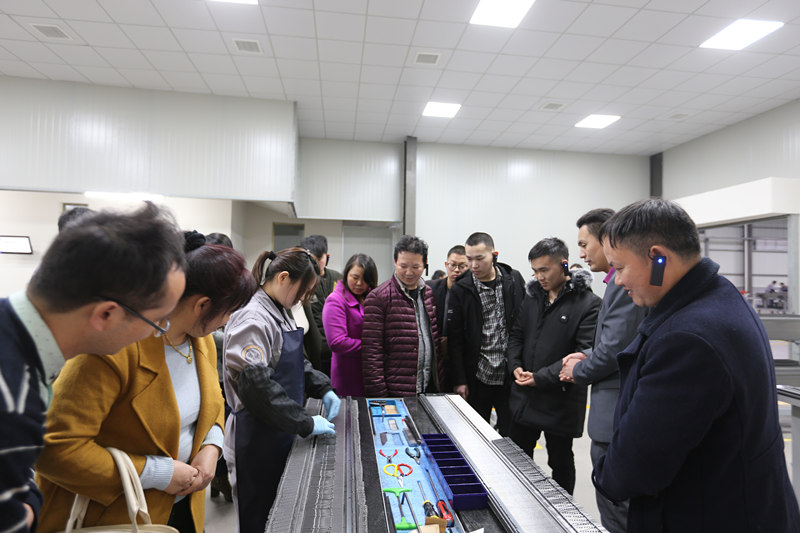

▲Clients communication

▲Guide of "Beworth tour in Golden autumn"

▲QC department

On site to experience and learn Beworth manufacture and quality, Beworth gave clients high confidence.

▲Visit assembly line

Dual U shape assembly line, 210m length, 50 assembly stations, every machine is assembled in 8 minutes.

QC Standard is showed head up screen.

▲Visited testing workshop

All machines are protected by cover and deliver to all of China.

▲Needle bed assembly

Needle bed is core parts of flat knitting machine, it requests strict condition. Needle bed workshop requests constant temperature and humidity to ensure needle bed quality.

▲Explaining needle bed bread-in principle

▲CNC workshop

Cam box is the key parts of flat knitting machine, importance like engineer to a car. Beworth equips Fanuc CNC to promote accuracy.

▲Cam box assembly line

Beworth has more than 10 years experience of manufacture of cam box.

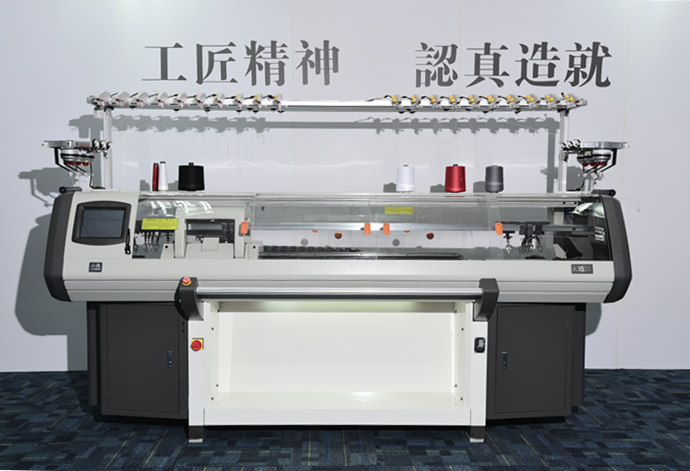

▲Exhibiting room and training center

Beworth not only designs pattern for customer, but also helps customers to train their own programmers and mechanists to grow up with customers together.

▲Exhibit machine

After visiting, clients stay in the garden to enjoy Beworth view.

We appreciated every customers to visited us, stay together to enjoy special Cixi sea food.